May 2024

May 2024

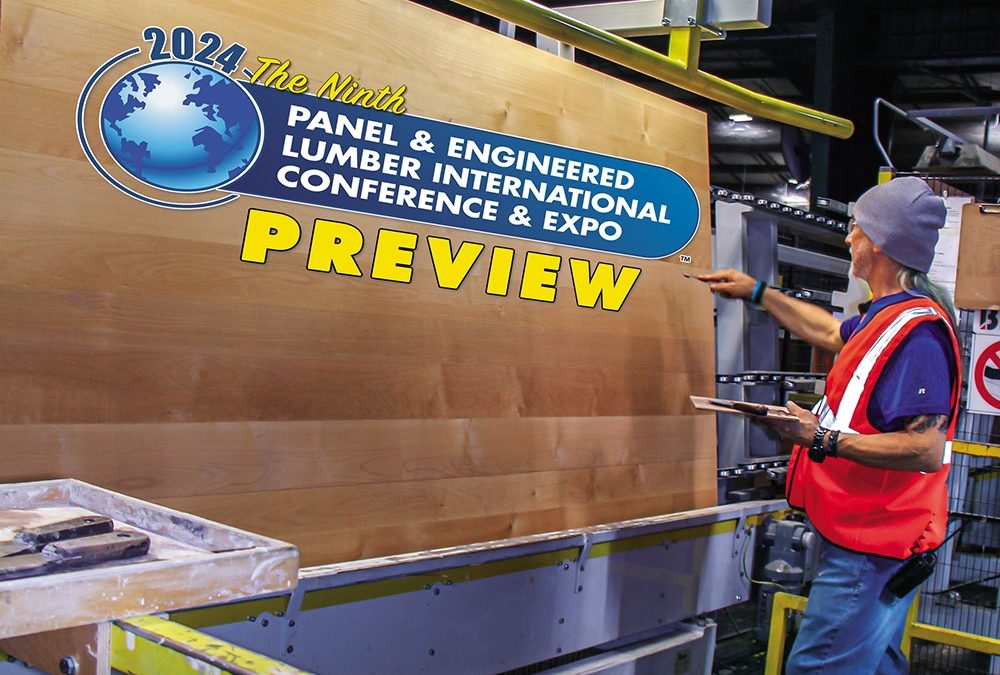

Cover: PELICE 2024 Speaks To The Panel Industry

Roy O. Martin, III of Martco and Stuart Gray of Roseburg led off the ninth Panel & Engineered Lumber International Conference & Expo (PELICE) held in mid-March in Atlanta.

Inside This Issue

PELICE 2024

The conference is unique in that it caters to both the structural and non-structural wood products segments.

SUBSCRIBE TO PANEL WORLD TODAY TO GET YOUR COPY OF THE ANNUAL DIRECTORY & BUYERS’ GUIDE

UPDATE

- Godfrey Announces OSB Mill For Maine

- Hoffman Acquires Besse Operations

- Roseburg Closes Missoula Particleboard

QUALITY CONTROL

- Andritz

- Argos Solutions

- Baumer

- Biele Group

- Büttner

- Dieffenbacher

- Electronic Wood Systems

- Fagus Grecon

- Grenzebach

- Hapco

- Hymmen

- IMALPAL

- IPCO

- LIMAB

- Raute

- Taihei Machinery

- Westmill

PROJECTS

- USNR Hybrid Dryer Bound For Boise

- Wisewoods Gears Up For More MDF

- Lignatherm Orders Andritz Refining

- Australian Panels Orders Air Cleaning

- Australian Panels Orders MDF Plant

- Rosboro Plans New Glulam Line

CLIPPINGS

- Ramm Named SR VP Of MFG

- Roseburg Names Strategic Director

- Cole Heads To The Hills

SUPPLY LINES

- Pallmann Takes Over Febs SK

- Siempelkamp Adds Digital Expertise

- Stiles Appoints Kellar As President

Find Us On Social

Number Nine Was Very Fine

Article by Rich Donnell, Editor-in-Chief, Panel World

Everybody seemed to have a really good time at the recent Panel & Engineered Lumber International Conference & Expo (PELICE) in Atlanta, from beginning to end, as the accompanying photos on this page would indicate.

Everybody seemed to have a really good time at the recent Panel & Engineered Lumber International Conference & Expo (PELICE) in Atlanta, from beginning to end, as the accompanying photos on this page would indicate.

PELICE wasn’t “brought to you” by Stella beer, but it sure looked that way, once Roy O. Martin of Martco placed three Stella beers on the first morning keynoters tables. As Martin explained, he was letting the world know that he pays off his bets, which in this case was an annual bet with the wife of yours truly on the LSU-Alabama football game, won last year by Alabama. The bet—a case of Stella—actually started some years ago between Roy’s late first cousin, Jonathan Martin, and my wife, May, and since Jonathan’s departure Roy has taken it on. You would be hard-pressed to find bigger LSU and Alabama fans than the Martins and my wife, respectively.

As an Auburn fan, well, I just have to put up with it.

While Stella kicked off the conference, the event ended with the traditional drawing out of a tumbler full of business cards for $500 cash. You have to be present to win, and Howard Hall of Huntsman, shown standing at right in the photo, indeed was, accepting the goods from Panel World Senior Editor Dan Shell. The rest of the audience as usual responded with a chorus of boos, and quickly headed for the exits, putting the final punctuation on the ninth PELICE.

PELICE is a relatively short event, lasting a day and a half, and it’s really a sprint from beginning to end for everyone to get the most out of it. And there’s a lot to get from 35 presentations, 100 exhibitors, and the numerous producers in attendance. Speaking of producers, a special thank you goes to the following producer companies that sent their personnel to PELICE. Sorry if we’re missing one or two, but here you go: Arauco—ATCO Wood Products—Boise Cascade—CalFibre—CIPA Lumber—Columbia Forest Products—Georgia-Pacific—Godfrey Forest Products—Gregory Log & Lumber—Hasslacher—Hood Industries—Huber Engineered Woods—Hunt Forest Products—JELDWEN—Langboard—Louisiana-Pacific— Mercer International—Pacific Woodtech—Peak Renewables—Plummer Forest Products—PotlatchDeltic—Roseburg—RoyOMartin—Scotch Plywood—States Industries—Tafisa Canada—TimberHP—Tolko Industries—West Fraser—Weyerhaeuser.

The next PELICE will be held April 16-17, 2026, and it will be the 10th PELICE since its inception in 2008. I’m sure there will be a special anniversary celebration. You can bet on it!

Want More Content?

Panel World is delivered six times per year to North American and international professionals, who represent primary panel production operations. Subscriptions are FREE to qualified individuals.

Newsletter

The monthly Panel World Industry Newsletter reaches over 3,000 who represent primary panel production operations.

Subscribe/Renew

Panel World is delivered six times per year to North American and international professionals, who represent primary panel production operations. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative. Contact us today!

Jarck spent the last two decades of his life trying build a high scale, commercial production TimTek (formerly Scrimber) composite lumber manufacturing facility, and nearly pulled it off; but long before then as a forest engineer he was a pioneer innovator of pulpwood loading and forwarding machinery, and log harvesting and processing machinery.

Jarck spent the last two decades of his life trying build a high scale, commercial production TimTek (formerly Scrimber) composite lumber manufacturing facility, and nearly pulled it off; but long before then as a forest engineer he was a pioneer innovator of pulpwood loading and forwarding machinery, and log harvesting and processing machinery.

One man who seemed to be on the verge of a product breakthrough, not with Scrimber, but with a product called Cross Laminated Strand Timber (CLST), was Graeme Black, CEO of Lignor in Australia. He died suddenly in East Melbourne on October 26, leaving behind an extended family. You may have met him when he made a presentation at PELICE in 2020.

One man who seemed to be on the verge of a product breakthrough, not with Scrimber, but with a product called Cross Laminated Strand Timber (CLST), was Graeme Black, CEO of Lignor in Australia. He died suddenly in East Melbourne on October 26, leaving behind an extended family. You may have met him when he made a presentation at PELICE in 2020.