One of the many intriguing tales to emerge from the Panel & Engineered Lumber International Conference & Expo held March 12-13 at the Omni Hotel in Atlanta was the plight of CalPlant I, the new rice straw-based medium density fiberboard plant…

Idaho Grant Helps College Train Woodworkers, Address Skill Gaps

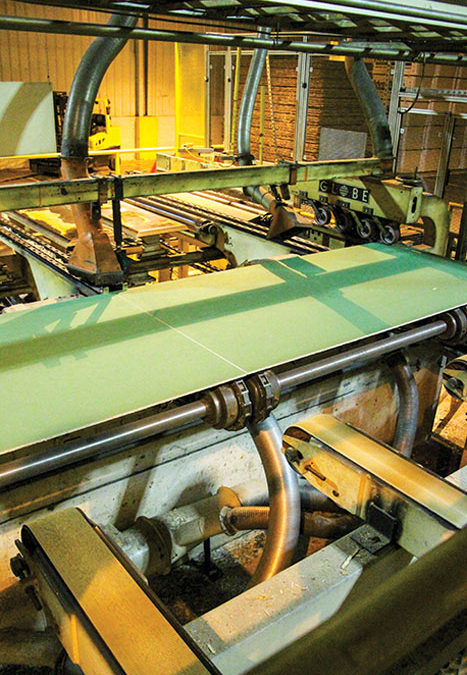

North Idaho College has been awarded a $482,582 grant by the Idaho Department of Labor to train more than 200 workers in the wood products manufacturing industry.

The two-year grant is a partnership with Lewis-Clark State College and five wood products manufacturing companies in North Idaho. The positions will pay wages ranging from $15 to $25 per hour plus employer-assisted medical benefits.

“This grant will go a long way in training the next generation of wood products manufacturing workers,” said NIC President Rick MacLennan. “These are solid, high-paying jobs and an outstanding opportunity for more than 200 people in North Idaho. We’re grateful for the Idaho Department of Labor’s foresight and the hard work put in by many people to make this grant a reality.”

The funds will be used to address skill gaps for high-wage, high-demand occupations in the forest products industry and increase the employment and wages of Idaho workers in mostly rural areas. The project also supports the Apprenticeship Idaho program, which expands innovative apprenticeships into high-growth occupations and industries. Idaho Forest Group, Potlatch Land and Lumber LLC, Stimson Lumber Co., Empire Lumber Co. and Plummer Forest Products (a total of 11 mills) are the five business partners in the grant. A match is required from industry partners, who gave a total of $141,834.61 in cash and in-kind donations.

The North Idaho College Wood Products Center of Excellence will provide training along with structured on-site training at the mills.

From Woodworking Network: https://www.woodworkingnetwork.com/news/woodworking-industry-news/grant-helps-college-train-200-woodworkers-addresses-skill-gap?ss=news,news,woodworking_industry_news,news,almanac_market_data,news,canadian_news