McClure Steps Down From AltecAfter a remarkable 50-year career, Allan McClure has stepped down from his role as General Manager of Altec Manufacturing, effective December 31, 2024. “Those familiar with the veneer and plywood industry know that Allan is among the best...

Tolko Announces Pino Pucci New President/CEO

tolko announces pino pucci new president/ceo

After 14 years as president and CEO (CEO) of Tolko, and more than 40 years with the company founded by his grandfather Harold, Brad Thorlakson has transitioned to the role of executive chair of the board. Further to this transition, Pino Pucci has assumed the role of president and CEO.

After 14 years as president and CEO (CEO) of Tolko, and more than 40 years with the company founded by his grandfather Harold, Brad Thorlakson has transitioned to the role of executive chair of the board. Further to this transition, Pino Pucci has assumed the role of president and CEO.

Pucci joined Tolko in 2015 as vice president, sales, marketing and logistics. With 35 years of industry experience, his innovative approach to leadership continues to inspire and challenge his teams to be their best and deliver results.

Pucci was appointed chief operating officer in September 2023. In that period, he prioritized listening and engaging with operational employees across the business, introducing Tolko’s new five-year strategy and becoming more familiar with Tolko’s production workforce, teams and assets.

“Pino’s unwavering commitment to safety, people and values have him well positioned to lead Tolko into the future,” Thorlakson says. “Tolko will remain a private, family-owned business and the family remains committed to the long-term success of the company.”

“I’m honored to build upon the generational legacy of the Thorlakson family,” Pucci says. “For over 65 years we’ve maintained a strong customer and people focus. This, coupled with Tolko’s values, have been the foundation of our success and are what will lead us moving forward.”

Latest News

McClure Steps Down From Altec

Arauco Plans MDF to OSB Conversion

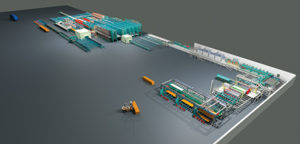

Arauco Plans MDF to OSB ConversionChile-based Celulosa Arauco y Constitución S.A. (Arauco) has selected Dieffenbacher to supply an OSB plant to replace an existing MDF line at its Trupan site in Cholguán in the Bío-Bío region of Chile. The plant is scheduled to start...

Weyco Expanding In Arkansas With EWP

Weyco Expanding In Arkansas With EWPWeyerhaeuser Co. has announced plans to invest approximately $500 million to build a new, state-of-the-art TimberStrand facility near Monticello and Warren, Ark., expanding the company's engineered wood products (EWP) capacity in...

Find Us On Social

Newsletter

The monthly Panel World Industry Newsletter reaches over 3,000 who represent primary panel production operations.

Subscribe/Renew

Panel World is delivered six times per year to North American and international professionals, who represent primary panel production operations. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative. Contact us today!