by Web Editor | Nov 26, 2010 | Taking Stock

Story by Rich Donnell,

Editor-in-Chief

Panel World magazine, as you may have realized, is published every other month. So its last issue of the year, such as the one in your hand, carries a November dateline; but in reality this issue is put to bed in late September, so when I say let’s review the past year, as I am now saying, I’m referring to late September 2009 to late September 2010.

I will say this, as bad as things have been, that late September 2009 and late September 2010 went a lot smoother than, say, late September 2008. You remember late September 2008 don’t you? The general economy was in a nosedive. Lehman Brothers had just filed for bankruptcy apparently because it couldn’t manage its subprime mortgage holdings. The stock market was collapsing. The building industry, which was already ill, went into a coma.

Since then, through late September 2009 and late September 2010, the building industry has emerged from its coma, though at times it still has difficulty recognizing some of the people in the room, and when it chooses to speak, its words aren’t always intelligible. It still has a lot more bad days than good days.

Here’s what happened during some of those days in the past year:

- A new business, Peninsula Plywood, decided to start operating the softwood plywood plant in Port Angeles, Wash., which had started up in 1941 under the name, Peninsula Plywood.

- Composite Panel Assn. took the position that the federal government’s Biomass Crop Assistance Program for renewable energy projects was an unfair subsidy program that could have disastrous consequences on wood-based industries.

- Murphy Co. geared up the idled Panel Products plywood plant in Rogue River, Ore.

- Arauco purchased Tafisa.

- Panel World magazine celebrated its 50th anniversary.

- Georgia-Pacific acquired the OSB facilities of Grant Forest Products.

- Duraflake started up a melamine lamination facility in Albany, Oregon, and celebrated 50 years of operation there.

- Uniboard produced its first MDF panel at its $160 million plant in Moncure, NC, part of which was moved from La Baie, Quebec and refurbished.

- The second Panel & Engineered Lumber International Conference & Expo was held in Atlanta, Georgia, featuring such excellent speakers as OSB industry entrepreneur John Godfrey.

- A bump up in markets during the early part of the year didn’t fool anybody that the recovery had truly begun.

- Composite Panel Assn. celebrated its 50th year, since its formation as National Particleboard Assn. in 1960.

- Long-time plywood equipment manufacturing specialist Dick Kerns died at age 74.

- EPA’s proposed Boiler Maximum Achievable Control Technology rules didn’t sit well with companies still immersed in a recession.

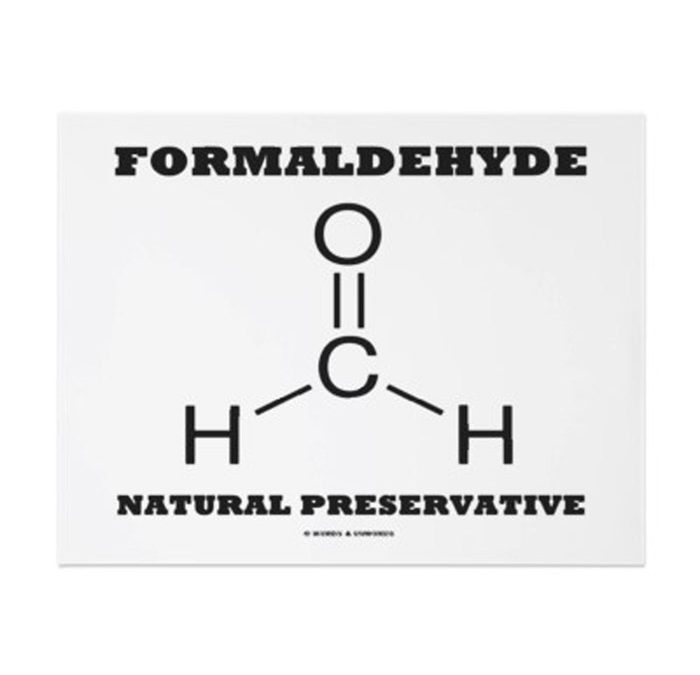

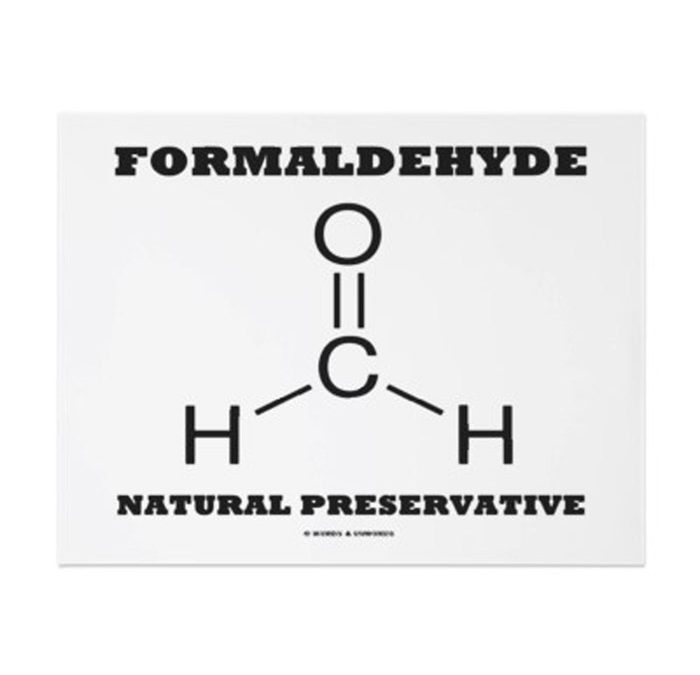

- The federal government passed into law a national formaldehyde standards act for board emissions that, while extremely strict, should level the playing field with regard to quality control, testing and enforcement.

- As reported in this issue, Momentive Performance Materials and Hexion merged to form a $7.5 billion resins giant.

- As also noted in this issue, our friend and former columnist, Professor Al Moslemi, died at age 74.

by Web Editor | Sep 26, 2010 | Taking Stock

Story by Rich Donnell,

Editor-in-Chief

I don’t know why I continue to do this, but several times each day I find myself going to marketwatch.com and getting the latest news on finances and stocks. As if I was a major player. True, I am a player in a major stock, Apple. But I am minor league material.

However, because I invested in Apple in late spring 2009, when it was 134, and today it stands at (wait, let me go to marketwatch.com) just above 255, it’s easy to fool myself into thinking I know what I’m doing.

But I have a secret to tell. It was my wife who first got us into Apple at 134. At about 150, I said let’s triple up. Along the way, as I mentioned in this space about a year ago, when Apple was a mere 190, we pulled some profits and bought—what else?—two Apple MacBooks.

But now we’re thinking big with Apple, as in using the profits to pay for my daughter’s wedding, though my daughter isn’t even engaged and is concentrating more on graduating in pre-med from the University of the South—Sewanee next year than planning a wedding (though a serious boyfriend lurks).

Perhaps by the wedding, whenever that is, Apple will hover near 400, as one “expert” has forecasted. Jeepers, that’s almost Googlesque. If that happens, we might have enough Apple profits to pay not only for our daughter’s wedding, but for all her school tuition loans.

You see, a lot rides on Apple in our family. Which is why recently I suffered great anxiety when Consumer Reports said Apple’s new iPhone 4 experiences reception issues when you hold the phone a certain way with your bare hand. I didn’t even know what an iPhone was, other than that Apple introduced it, which immediately made it significant in my daughter’s future wedding plans. The stock nosedived for several days, maybe down to 235 even, and I had visions of my daughter eloping, until Apple chief Steve Jobs made a special appearance to address the issue, and advised users to hold the phone a different way.

Whew! That was close. But the crisis was quelled, and since then Apple has been on the rise again.

So I guess in essence I go to marketwatch.com each day to see how my daughter’s future wedding plans are progressing as well as the payments on her loans.

One thing I have learned in making these daily visits to marketwatch.com is that there’s a good chance the market will react in just the opposite of what the main headline says. That is, when the headline and story is negative (“Oil Spill Darkens Sentiment”), the market turns positive, and when the headline and story is positive (“Oil Spill Stoppage Brightens Sentiment”), the market goes negative. I wasn’t going to reveal this investment insight, but I like you guys.

Of course I’m wondering what the Oil Spill has to do with investing in stocks anyway. I have another secret to reveal. The reason I tripled our investment in Apple was because Apple was also the name of the Beatles’ record company, and I’ve always been a big Beatles fan. Sometimes it pays off to tie up loose ends.

by Web Editor | Jul 26, 2010 | Taking Stock

Story by Dan Shell,

Managing Editor

Back in early 2008, I remember first hearing about some type of new federal pilot program with matching payments for collecting and hauling biomass that would start with around $20 million bucks. Now, $20 million isn’t so much in the overall context of federal spending these days—call it the equivalent of a stock trader’s cup of coffee considering the trillions thrown at the investment banking sector, or a couple hours of war. I also remember thinking that $20 million for biomass shipments would disappear pretty quick.

Flash forward two years, and the Biomass Crop Assistance Program has exploded, with costs projected at $2.1 billion over the next 10 years. Until it was temporarily suspended in February because of its controversial impact on existing biomass and mill residual markets and lack of progress towards the goal of developing new sources of renewable fuels, more than $185 million in payments had been made in little more than 6 months—with another $100-plus million authorized and currently being processed.

So much for that cute little $20 million “pilot program.”

Previous issues of this magazine as well as this one have contained much coverage and background on the panel industry’s response to the Dept. of Agriculture’s Farm Service Agency soliciting public comments and modifying BCAP to better focus its efforts on developing and utilizing new sources of biomass, not disrupting existing markets and raising residual costs. A new and improved BCAP is due to resume later this year. Outside of that technical rule-making effort is the federal budget appropriations process to fund BCAP as part of the 2012 Farm Bill that’s currently gaining weight in Congress.

Even in a Congress that spends money like it’s burning a hole in the U.S. Treasury, it hasn’t gone unnoticed that BCAP is poised to become a giant agricultural subsidy. During recent Congressional hearings on BCAP, one appropriations committee member noted BCAP costs have risen 3,000% faster than original budget projections.

A new reason for the pending BCAP cost explosion is a provision added to the proposed “new and improved” BCAP: In addition to providing matching payments for collecting, storing and hauling biomass, the government will now pay biomass growers up to 75% of their “crop establishment” costs. That sound you hear is the subsidy door being blown wide open and off its hinges once BCAP gains traction as a row-crop subsidy.

Congressman Jack Kingston of Georgia said at a recent hearing, “If we don’t kill it now, it will have its own lobbying group. It has a constituency growing.”

While there are plenty of ways for government to get involved and help develop various incentives for alternative energy utilization, is having the federal government inject raw cash payments into developing markets the right way to go? Or will that just produce distortions in economic activity that’s occurring anyway?

USDA Farm Service Agency Administrator Jonathan Coppess says the the final BCAP rule will “unleash the full potential of the BCAP program.”

Yet seeing BCAP “unleashed” is exactly what many in the panel industry are worried about.

by Web Editor | May 26, 2010 | Taking Stock

You’ll Find A Mill In Moncure

Article by Rich Donnell, Editor-in-Chief, Panel World May 2010

You’ve probably already noticed on the cover of this issue, and you’ll notice beginning on page 10 in this issue that Uniboard’s new MDF/ HDF plant in Moncure, North Carolina is in the spotlight.

To begin with, if you’re driving from, say, Atlanta, or farther up the interstate at Charlotte, it’s not easy to get to Moncure. I mean you can take the interstate up and around to Raleigh and then backtrack southwest to Moncure, but that’s no fun. Which means, you’ll be taking the highways near or through the likes of Concord and Asheboro, and Siler City and dipping down to Sanford before shooting back up to Moncure, and which also means you might be calling your mill appointment in Moncure and asking for another 30 minutes because it seems like you’ve been running in place.

Actually it’s a nice drive; the kind of drive that allows you to gather your thoughts. Some of my thoughts concerned the Moncure mill property, where Uniboard has built its new MDF plant and on which Uniboard also operates a particleboard plant and melamine laminating operation.

I was thinking about the site’s different owners through the years. But I was mistaken on my premise that Weyerhaeuser had been the original owner. Tom Ruedy, the Uniboard Director of Business Development of Moncure MDF & HDF, quickly set me straight when I finally reached the plant.

Evans Products had started up an MDF plant here in 1971, Ruedy told me. Then Weyerhaeuser bought it in 1974. Ruedy, after graduating from Virginia Tech, had gone to work for Weyerhaeuser at its corporate headquarters in Tacoma, before Weyerhaeuser sent him to Moncure in 1978 as a quality control guy, and he hasn’t strayed too far since. Weyerhaeuser owned the operations until 1999, and I say “operations” because Weyerhaeuser started up a new particleboard plant in 1987. In 1999, Weyerhaeuser sold its Moncure operations to SierraPine. SierraPine stayed around until most of 2004, when it sold to ATC Panels. Then Uniboard bought the complex, which included a melamine laminating operation in addition to the particleboard plant, and the inoperable remnants of the old MDF plant.

Something that caught my eye as I was driving into the area was the Moncure Plywood mill just down the road. A little research revealed that it started up more than 40 years ago as Triangle Plywood, then became Boise Cascade, then Williamette Industries, then Weyerhaeuser Co., and in 2004 became Wood Resources LLC of Atlas Holdings. It had been through a labor strike through parts of 2008-2009. It was still operating when I drove by it.

I don’t know of what value any of this information is to you. I do know that as I departed Moncure, my thoughts steered toward the people who had worked on these grounds through the years—their skills, their ambitions, their families. I also thought about all the new technologies that had been implemented and replaced with newer technologies, right up to Uniboard’s new plant.

I guess some old mill sites never die, they don’t even fade away (especially if the regional timber resource remains viable and accessible). At least that appears to be the case in Moncure, North Carolina.

The monthly Panel World Industry Newsletter reaches over 3,000 who represent primary panel production operations.

Panel World is delivered six times per year to North American and international professionals, who represent primary panel production operations. Subscriptions are FREE to qualified individuals.

Complete the online form so we can direct you to the appropriate Sales Representative. Contact us today!

by Web Editor | Mar 26, 2010 | Taking Stock

Story by Rich Donnell,

Editor-in-Chief

On page 14, we publish an article written in 1980 by the founding editor of Plywood magazine. The article celebrates the magazine’s 20th birthday. In 1960, Jim Burrell, that editor, charted the course that Plywood magazine, Plywood and Panel magazine, Plywood and Panel World magazine and Panel World magazine would continue to follow for 50 years. Sure there has been considerable tweaking along the way—such as to the name of the magazine—but the editorial and advertising plan hasn’t veered much.

Three years after Burrell wrote that article, I joined Hatton-Brown Publishers Inc. and its slew of forest industry trade journals, one of which, Plywood and Panel, had been acquired only a year or so before. By the time I started, Hatton-Brown had re-named it Plywood and Panel World, and even formed a separate company to encompass it. This means that I’ve been associated with the magazine for more than half of its 50 years.

I’ve always found the magazine to be especially stimulating. One reason is because of its international presence; another reason is because of the diversity of industries that comprise the panel industry; but most importantly because of the vibrant companies and people that Panel World writes about.

I have so many stories in my head of mills, companies and people I’ve encountered along the way. But one story I especially recall is this:

In 1988, I traveled to several machinery manufacturers in Germany with our overseas sales rep, the Englishman, Alan Brett. It was my first trip abroad, and Alan had drawn up a rigorous schedule of interviews and factory tours. One of our visits was to Schenck, the forming machine manufacturer located in Darmstadt.

You have to keep in mind that I had been a sportswriter. The X’s and O’s of a football game plan can get pretty complicated, but it’s nothing compared to “wind sifting,” which was what Schenck was all about.

I remember when we pulled up to the old Schenck factory. It certainly intimidated an international novice like me. People in Germany weren’t speaking as much English back then, so basically Alan steered us with his broken German into a dark conference room where I would interview one of Schenck’s technology specialists. I had prepared a list of questions for our technology “rap” session.

Then Günter Natus entered the room. He looked very serious, very German. His English was good, but it still sounded very German. “I know Plywood and Panel World,” he said. “I see that you are expanding beyond the coverage of only plywood and into particleboard.”

This of course was the purpose of my trip: to show companies such as Schenck that we intended to emphasize all panel and board products and technologies. If Günter recognized it, we must be on the right track.

I tossed several “technical” questions at Günter, and he was kind enough to answer them as if I understood what he was talking about, though we both new I didn’t.

Nevertheless, I left the meeting thinking two things: that I can do this panel industry beat; and that Günter Natus is in the top five of the smartest people I have ever met.

Well, I’m still here, and so is Günter (with Dieffenbacher). We cross paths now and then, most recently at the Panel World PELICE event in Atlanta in early February. He’s still in my top five. I’m still on the panel industry beat.

by Web Editor | Jan 23, 2010 | Taking Stock

Story by Rich Donnell,

Editor-in-Chief

The second PELICE (Panel & Engineered Lumber International Conference & Expo) will be held February 4-6 at the Omni Hotel at CNN Center in downtown Atlanta, Georgia. It seems like a lifetime ago since the first PELICE was held at the same locale in early 2008.

Do you remember early 2008? The economic numbers had become unsteady. Oil prices were still astronomical. Housing was on the wane. There was talk of a possible recession. But we were viewing it as just another downward lull on the chart of ups and downs in a cyclical industry. “It might get a little worse, but probably won’t last long,” we were told and we told ourselves. It didn’t seem to be anything we hadn’t experienced before. The economy was but one of many topics that the presidential candidates were debating.

Within the year, our economy was on the verge of extinction, the cause of which was reckless lending practices geared to the housing market—practices which international investment entities even more recklessly shaped into various debt investment vehicles. Then when lots of borrowers said they couldn’t afford it, our economy collapsed and the world’s with us. Scenes on television resembled those disaster movies that show sections of the world in utter chaos…“In Europe…In Asia…In Russia…and in the United States…”

And it’s still shaky, but after a major capital infusion by our government into our economy, it has at least settled down. There is even some growth in the economy, which there should be, given the old adage “there’s nowhere to go but up.” Of course we suspect that much of this growth is artificial because of the government input, and we wonder about government debt, and we think that until jobs come back we’re not there yet.

We’ve all become amateur economists since early 2008. But that’s not who we are. We’re professionals in the forest products industry, and we run panel plants as efficiently as possible with the latest technologies, in order to manufacture the products we think our companies are best suited to produce. That’s what we do, whether or not the marketplace is craving our products.

Maybe it’s not as simple as that. When the federal government puts the squeeze on our resin emissions and our air emissions, we have to become almost perfect in our plants in order to find profit margin.

Which brings us to PELICE this February in Atlanta. Here you will become up to date on the latest resin technologies and the latest air control technologies, as well as the latest plant machinery technologies and systems. You will hear about the scramble for woody raw materials, and how the emerging wood bioenergy industry is affecting this scenario. You will hear more about the relationship between what a plant produces and what builders want, and how “green” building preferences continue to impact both. You will hear about one company’s launch of an engineered wood product at a converted OSB plant.

You will also hear forecasts about the wood products industry and about the general economy. Many economists are a little gun shy these days because they didn’t see the tsunami. But don’t be too hard on them. Aw, the heck with it. Be hard on them! See you at PELICE!