by Web Editor | Dec 27, 2012 | Update

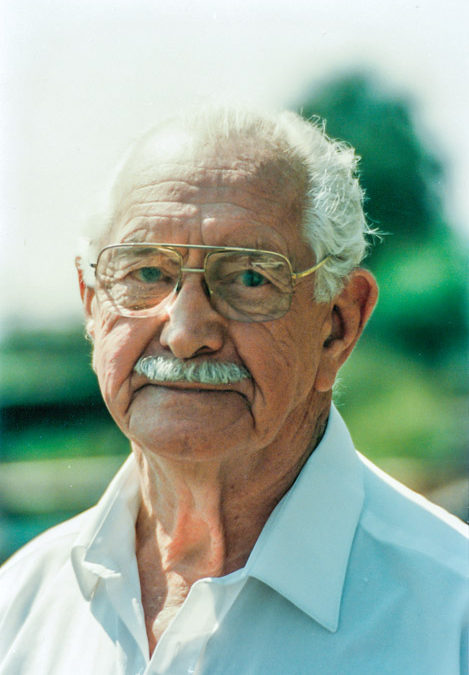

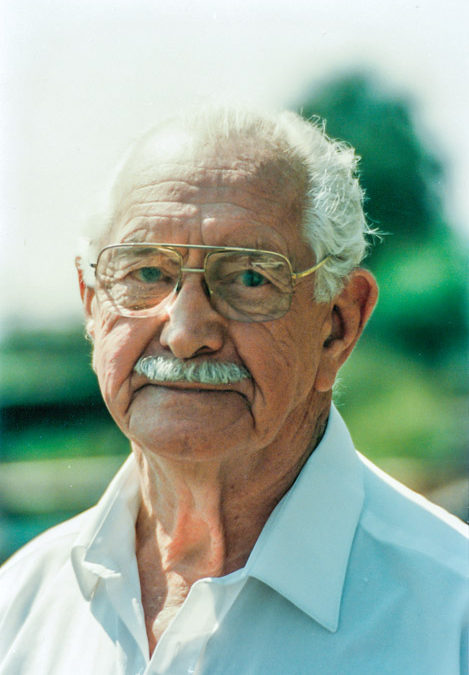

Harry (Bud) Calvert, a major participant in the plywood industry and principal of Calvert Manufacturing, died May 20. Calvert, a longtime resident of Oak Hill, Fla., was 97.

Harry (Bud) Calvert, a major participant in the plywood industry and principal of Calvert Manufacturing, died May 20. Calvert, a longtime resident of Oak Hill, Fla., was 97.

Calvert was born in Wantagh, NY in 1914. He studied aeronautical engineering at Tri-State College in Angola, Ind., and then worked for GMC Truck in Pontiac, Mich. In 1936, he entered the Boeing School of Aeronautics in Oakland, Calif. and until the end of World War II he worked for Boeing Aircraft in Seattle, Wash.; American Central Manufacturing in Connersville, Ind.; and Consolidated Vultee Aircraft at Allentown, Pa. and Fort Worth, Tex. His responsibilities ranged from student-riveter to inspection supervisor on the B-17 Flying Fortress, to chief inspector on the Dive Bomber and B24 Liberator components, to sheet metal foreman and assistant superintendent on the TBY Torpedo Bomber to engineering salvage supervisor and inspector on the B-36 prototype.

In 1946 Calvert moved to Boring, Ore. and started Calvert Machine Service as a one-man machine and welding shop, working mostly in the sawmill trade. He bought Preston Woodworking Machinery of Preston, Ontario in 1958. Preston was a full dealership for Coe Manufacturing.

In 1962, Calvert became a consultant in development and troubleshooting for Coe worldwide, and spent six months in residence at the new U.S. Plywood-Temple Industries mill in Diboll, Tex. Calvert designed a hydraulic servo operated backup roll for the mill.

Calvert left Coe and in 1975 moved to Longwood, Fla. and started Calvert Manufacturing as a job shop, which expanded into specialty replacement and upgrading of machines common to southern pine plywood production such as chargers, carriage elements and other lathe parts. Calvert also developed new technologies such as wide contact backup rolls, knife edge roundup sensing technology and floating pressure bar technology.

Calvert was known as a free spirit and led an adventurous life. He made his first attempt at hang gliding at Kitty Hawk on his 80th birthday. He had a lifelong passion for flying and a great love of nature and animals.

The monthly Panel World Industry Newsletter reaches over 3,000 who represent primary panel production operations.

Panel World is delivered six times per year to North American and international professionals, who represent primary panel production operations. Subscriptions are FREE to qualified individuals.

Complete the online form so we can direct you to the appropriate Sales Representative. Contact us today!

by Web Editor | Nov 2, 2012 | Update

Allyn Ford, president and CEO of Oregon-based Roseburg Forest Products, announced the promotion of Grady Mulbery to Vice President of Manufacturing for the company. In this newly created position Mulbery will oversee all manufacturing facilities throughout the company, including composites, lumber, engineered wood, plywood and veneer.

Mulbery joined Roseburg in January 2011 as the Vice President of Manufacturing for the composite panel business. Prior to joining Roseburg, he was with SierraPine LTD and has held positions with Weyerhaeuser and Willamette Industries as director of operations, regional manager, general manager and plant manager and has extensive experience in particleboard, medium density fiberboard and laminated-veneer lumber (LVL) operations. He has also been responsible for research and development efforts in the area of wood/plastic composite products.

by Web Editor | Aug 21, 2012 | Update

Multiple fingerjointing lines and edge gluing production will be part of a $250 million wood processing complex to be built in Winslow, Ariz. by Pioneer Associates, based in Billings, Mont.

The project will also comprise a small log sawmill along with 20 dry kilns for the production of pine lumber that is to be fingerjointed, edge glued and otherwise engineered into door products, window frames and furniture components. The complex is expected to employ 280 while adding another 160 jobs related to logging. The operation will receive 115 truckloads of logs daily.

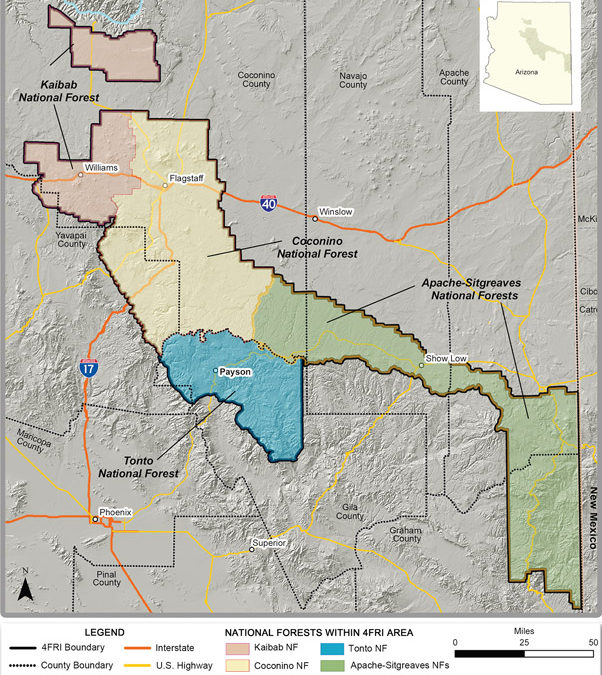

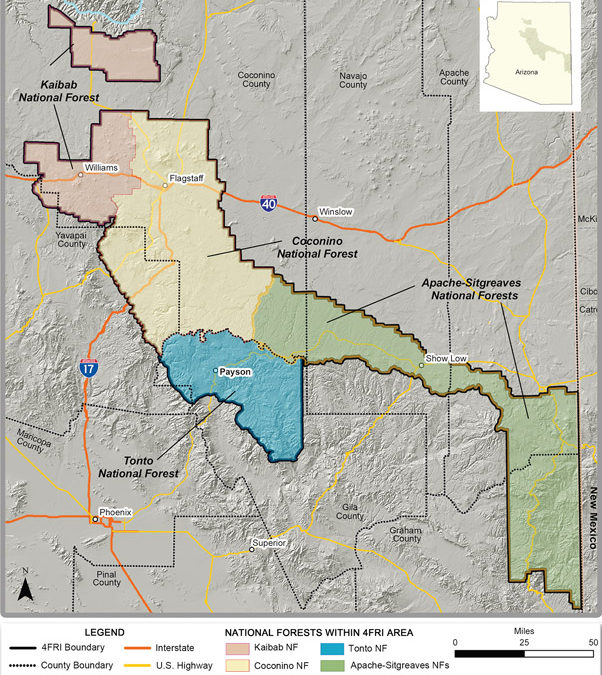

Pioneer Associates recently received a federal government contract to thin 300,000 acres over 10 years as part of the the federal Four Forests Resource Initiative (4FRI), which aims to restore 2.4 million acres of ponderosa pine timberland on the Cococino, Kaibab, Apache-Sitgreaves and Tonto national forests.

The new sawmill in north central Arizona will utilize an innovative batch processing concept from Adco-Designs. While traditional batch systems have sorted incoming logs by diameter to reduce throughput and saw set variation, the concept here is to scan, optimize and process logs through primary breakdown, then sort cants into “solution” batches that will allow downstream machines to maintain constant sets per the solution being sawed.

According to Adco’s Rich Landers, the system will allow machine centers to run slower and more accurately while also maintaining production due to the lack of gaps between individual pieces. “It will be more like a ribbon-cutting system, with thin kerfs and slower speeds,” he says.

The operation will utilize stems smaller than 14 in., while larger logs are scheduled to go to Precision Pine & Timber in nearby Heber, though large logs are expected to only make up 3% of overall volume.

In addition to using its fiber waste to generate steam for the kilns, heat for the mill and power production, Pioneer Associates plans to construct an adjacent biofuels production facility.

Pioneer has already been in project discussions with Concord Blue Energy, a Las Vegas-based subsidiary of a German waste management company that specializes in turnkey general contracting and engineering for the implementation of waste to energy projects, and offers its own gasification and combustion technologies.

Pioneer Associates won the thinning award with a $6.3 million bid. This created some controversy because another company, Arizona Forest Restoration Products (AZFRP), offered $15 million. AZFRP planned to build an oriented strandboard plant. Pioneer apparently won the award because its wood products operation is not expected to be so commodity-driven while also bringing along an environmentally correct biofuels plant.

However, AZFRP noted after the award announcement that Pioneer’s products will be destined for the same housing and commercial construction markets as AZFRP’s products would have been. Company officials also questioned how the government could regard as low risk a proposed cellulosic biodesel plant as a viable project “when apparently not a drop of cellulosic biodiesel has ever been produced outside of a research facility.”

Pioneer Associates hopes to begin site development by the end of this year and start up the sawmill by late summer next year, with the biofuels plant to come a little later. Pioneer has unsuccessfully shopped its small log production complex concept in Canada and New Mexico in the past, but a lack of sufficient timber supply turned away those efforts.

Ongoing drought conditions and overstocked forests have combined to heavily impact Arizona, where several major forest fires have occurred the past few years. Federal officials in the region had long seen the need for forest health restoration efforts, but with no new funding and a severely limited market for the small timber and other barely merchantable forest residuals, a new approach was needed to create economically viable forest products capacity to handle the low-grade material resulting from timber stand management activities.

As 4FRI team leader Henry Provencio notes, “We asked industry what was needed for them to move back to northern Arizona. The reply was a long-term commitment of supply, sufficient to meet the investment we are asking them to make. In order for us to meet that kind of commitment and meet the restoration needs of our forests, we had to go big.”

by Web Editor | Aug 21, 2012 | Update

Soy Fiber Based Plant Starts Up

Agristrand Mankato, LLC reports that production has commenced at its 160,000 sq. ft. manufacturing facility in Mankato, Minn. Agristrand is a manufacturer of “eco-friendly” soy fiber based soyboard and soycore and says its fiber is regionally sourced, annually renewable and products contain no added formaldehyde (NAF).

The manufacturing facility was purchased in November 2011, and has undergone major transformations with the addition of a proprietary fiber processing plant and many upgrades and improvements to produce a fully automated production line. The plant is currently rated at 40MMSF production capacity.

Agristrand will be taking advantage of this upcoming soybean harvest and is working with producers on best practices to harvest a superior fiber for its niche board production. The soy straw is a waste product as a result of the soybean harvest and would typically be chopped and redistributed onto the field. Agristrand’s soy acquisition team is contracting with farmers for approximately 45,000 acres of baled soy straw from an area within a 75 mile radius of Mankato.

Agristrand Mankato, LLC is the embodiment of many years of research and development. It began when four company founders, Thomas Neel, Timothy McDermott, William Priestly and Barry Monahan, began looking for an ag-fiber based alternative to wood based OSB as the market began to fluctuate in 2005. Many agricultural fiber alternatives were explored including corn, wheat and soy straw. Significant time was spent evaluating each fiber’s makeup then deciding that soy was the best alternative based on preliminary study. The founders determined which processes best matched the benefits of soy and oversaw a commercial run on full sized equipment. They concluded there was merit to finding a way to produce a composite board product utilizing soy fiber in a full scale commercial facility.

Company representatives, as well as forest product consultants, spent time at the USDA’s Forest Products Laboratory in Madison, Wis. to better define the processes for conditioning the fiber. Under the watchful eye of forest industry professionals a higher value soy fiber based MDF and particleboard was made realizing excellent properties. It was determined that conditioned soy fiber would perform very well based on the proprietary process utilized by Agristand.

Determining that the startup of a greenfield project was out of reach given the then economic times, the company began soliciting input from larger producers of particleboard and MDF interested in the possibility of utilizing soy fiber as an additive, or blend, with wood fiber. In late 2010, Company President Neel was approached by a representative of the bondholders of the recently shuttered facility in Mankato, Minn., which had manufactured a wheat fiber composite board product.

Agristrand Biocomposites, LLC began evaluating the opportunity and the possibility of converting the plant from wheat to soy and ultimately decided to pursue it. The location boasts a potential fiber source of 1.2 million acres within a 75 mile radius of the plant. Agristrand Mankato, LLC was born and acquired the assets of the board plant facility. There was considerable cleaning, deferred maintenance and upgrades to make the changeover to a soy based composite board product.

Today Agristrand Mankato, LLC reports it is the only manufacturer in North America of soy fiber based particleboard and door core products. “We have successfully meshed the interests of the nearby agricultural community with the interests of the building products industry,” the company states. “We have done this by employing people with agricultural experience as well as those from the composite board industry. With the inclusion of our proprietary front end conditioning equipment and methodology we are able to utilize a process that is similar to a typical board plant.”

Agristrand’s goal is to be a top quality producer of ag-fiber based particleboard and door core products. “Within this industry niche market we have found widespread support and interest from customers requesting ‘green’ alternatives,” the company states. “In today’s competitive environment the importance of supplying a sustainable product as a viable, competitive option is important.”

The monthly Panel World Industry Newsletter reaches over 3,000 who represent primary panel production operations.

Panel World is delivered six times per year to North American and international professionals, who represent primary panel production operations. Subscriptions are FREE to qualified individuals.

Complete the online form so we can direct you to the appropriate Sales Representative. Contact us today!

by Web Editor | Aug 16, 2012 | Update

Weyerhaeuser Rebuilds Force

Weyerhaeuser Co. reports it is hiring additional trades and production workers at its engineered lumber products plants in Natchitoches and Zwolle, La., and Emerson, Ark.

“We are gearing up to ensure continuing product availability for our customers as demand for housing and light commercial construction recovers,” says Carlos Guilherme, Vice President of Engineered Lumber Products for Weyerhaeuser.

The Natchitoches plant manufactures Trus Joist TJI joists and Trus Joist Microllam laminated veneer lumber (LVL). The Zwolle and Emerson plants manufacture veneer and plywood.

The monthly Panel World Industry Newsletter reaches over 3,000 who represent primary panel production operations.

Panel World is delivered six times per year to North American and international professionals, who represent primary panel production operations. Subscriptions are FREE to qualified individuals.

Complete the online form so we can direct you to the appropriate Sales Representative. Contact us today!

by Web Editor | Aug 16, 2012 | Update

Louisiana-Pacific appointed Curt Stevens to succeed Rick Frost as LP CEO effective in May. Frost, who served as CEO since 2004, retired from LP May 31.

Stevens, 59, joined LP in 1997 and has held senior management positions throughout his career at the company. He was appointed to the interim position of executive vice president, chief operating officer in December 2011. Previously, he served as executive vice president, administration and chief financial officer from May 2002 to December 2011. From September 1997 to April 2002, Stevens served as vice president, treasurer and chief financial officer.

Retiring CEO Frost comments, “I have been honored to have had the opportunity to lead LP over the past seven years. During some of the toughest times the building industry has ever seen, our people have improved operations, quality and market share while leading the industry in safety. Appointing Curt as CEO provides LP continuity with an experienced leader who is well prepared to address LP’s future challenges and opportunities.”

Stevens comments. “LP has exceptional people, quality products, and the financial position to take full advantage of an upturn in the housing market. Great things await us.”

LP has also promoted Brad Southern to senior vice president and general manager, Siding; and Brian Luoma to senior vice president and general manager, Engineered Wood Products. Southern and Luoma will report to CEO Stevens.

Southern joined LP in 1999. He has led LP’s Siding business since 2005 and was previously vice president of specialty operations. Luoma joined LP in 1987 and has headed the engineered wood products business since 2006.

Harry (Bud) Calvert, a major participant in the plywood industry and principal of Calvert Manufacturing, died May 20. Calvert, a longtime resident of Oak Hill, Fla., was 97.

Harry (Bud) Calvert, a major participant in the plywood industry and principal of Calvert Manufacturing, died May 20. Calvert, a longtime resident of Oak Hill, Fla., was 97.