Walmart Home Office Installs Mercer CLT, Glulam Mercer Mass Timber (MMT), a manufacturer of timber building materials and a subsidiary of Mercer International Inc., has announced the completion of a key role in the construction of Walmart’s new Home Office in...

March 2025

March 2025

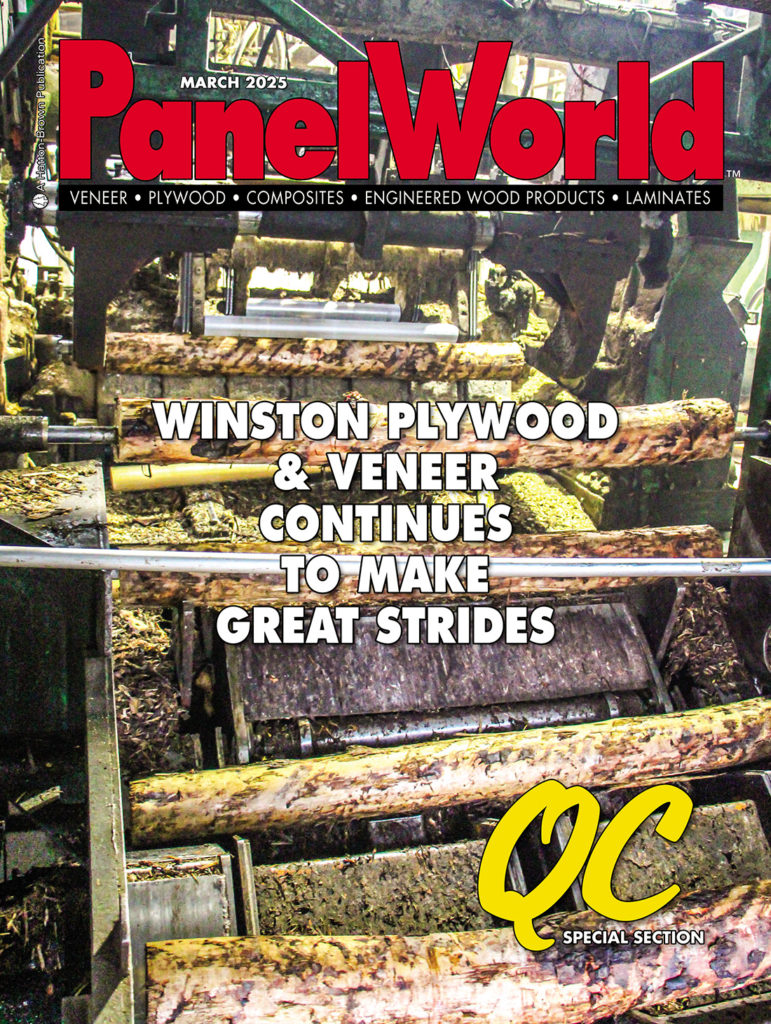

COVER: Winston Plywood & Veneer Continues To Make Great Strides

Eight years since its startup, which followed a destructive tornado, Winston Plywood & Veneer continues to make its mark as a bigtime producer of plywood, while building up a culture of safety and teamwork.

Inside This Issue

WINSTON PLYWOOD & VENEER HAS THE COURAGE TO CARE

Winston Plywood & Veneer has found safer footing in recent years.

SUBSCRIBE TO PANEL WORLD TODAY TO GET YOUR COPY OF THE ANNUAL DIRECTORY & BUYERS’ GUIDE

UPDATE

- New OSB Project

- FS Old-Growth Amendment Nixed

- Douglas Retires From Scotch

- BC Refocuses On Timber Sales

EUDR - Exactly What Is It?

ABC’S Of Pending EUDR And Potential Impact On NA Wood Products

QC

- Argos Solutions

- Baumer

- Biele Group

- Camsensor

- Dieffenbacher

- Fagus Grecon

- Hapco

- Hymmen

- IMALPAL

- LIMAB

- Siempelkamp

- Taihei Machinery

- USNR

PROJECTS

Rethinking The Panel Repair Process With Automated Edge-Damming

RoyOMartin implements new Con-Vey technology on trimmed panels.

CLIPPINGS

- GP’s Neal Leads Building Products

- Roseburg Names Plant Managers

Find Us On Social

Some Stories Are Worth Retelling

Article by Rich Donnell, Editor-In-Chief, Panel World

Has it been 10 years? Indeed it has, when officials of Winston Plywood & Veneer and the governor of Mississippi gathered in early 2015 at a groundbreaking ceremony for the company’s new plywood mill in Louisville, Miss.

Has it been 10 years? Indeed it has, when officials of Winston Plywood & Veneer and the governor of Mississippi gathered in early 2015 at a groundbreaking ceremony for the company’s new plywood mill in Louisville, Miss.

The ceremony was a game-changer for the city, which had taken two major hits in recent years. The more recent was a tornado on the evening of April 28, 2014. The intense storm killed 10, injured dozens more, and swept away homes and structures, including a plywood plant that Georgia-Pacific had shut down in 2009, which was the other major hit to Louisville, as those mill workers and families lost their livelihoods.

GP began construction of the Louisville plywood mill in 1964, during the birthing era of southern pine plywood manufacturing. GP was already running a plywood mill at Fordyce, Ark. and starting up one in Crossett, Ark. The Louisville plant was one of four more where GP would report real production beginning in 1966.

So it goes without saying the new brownfield plywood mill ceremony in 2015 was a breath of fresh air for the community and the area. Actually an Oregon-based firm had come in before the storm and planned to put the existing plant back into operation, before Winston Plywood & Veneer of Atlas Holdings soon took charge.

Atlas Holdings had started in 2002 with the purchase of a small paper mill in Indiana, but today operates more than two dozen companies and several hundred facilities in various industries, including wood products. According to a statement on its web site, “Atlas specializes in a unique, focused approach to buying and building our businesses, often centered on investing in operating companies undergoing complex operational and financial challenges.”

That’s somewhat of an understatement for what it encountered at Louisville following the destruction of the old plywood mill. With the cover story of this issue, Panel World editors have now visited and written about the Winston facility three times. Each story has had it own theme: rising from the ashes; working through COVID; a growing culture of health and safety.

It hasn’t been easy for Winston Plywood & Veneer. Initially, following considerable demolition, it salvaged and rebuilt some of the equipment that survived the tornado, and through the years has enhanced production and efficiencies through the installation of newer machinery. An overdue emphasis on employee relations and health has surged in recent years. Several of those on the company’s leadership team have been with the company for most if-not-all of its duration, and they’ve continued to refine the skilled personnel on the plant floor.

Who knows what our next visit and next Winston story will entail. It’s sure to be worth telling.

Want More Content?

Panel World is delivered six times per year to North American and international professionals, who represent primary panel production operations. Subscriptions are FREE to qualified individuals.

Newsletter

The monthly Panel World Industry Newsletter reaches over 3,000 who represent primary panel production operations.

Subscribe/Renew

Panel World is delivered six times per year to North American and international professionals, who represent primary panel production operations. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative. Contact us today!

Jarck spent the last two decades of his life trying build a high scale, commercial production TimTek (formerly Scrimber) composite lumber manufacturing facility, and nearly pulled it off; but long before then as a forest engineer he was a pioneer innovator of pulpwood loading and forwarding machinery, and log harvesting and processing machinery.

Jarck spent the last two decades of his life trying build a high scale, commercial production TimTek (formerly Scrimber) composite lumber manufacturing facility, and nearly pulled it off; but long before then as a forest engineer he was a pioneer innovator of pulpwood loading and forwarding machinery, and log harvesting and processing machinery.