BID Group and Biomass Engineering & Equipment (BE&E) announced a strategic supply and outsourcing partnership, in which BE&E will acquire the Vibrapro brand and manufacturing operations located in Boise, Id., and the BID Group fabrication plant in Greenville, Ky…

July 2023

July 2023

Cover: Simsboro Still Gets It Done For Roseburg

SIMSBORO, Louisiana – If you want to see a plant that can survive, you’re looking at it. Nestled off I-20, in a town so small the state of Louisiana calls it a village (the 2021 population estimate was 791) there runs a particle-board plant—first built by Willamette in 1971, assumed by Weyerhaeuser in 2001 as part of the Weyerhaeuser purchase of Willamette, then Flakeboard purchased it in ’06 (installing a melamine lamination line in 2009), and then sold to current owner Roseburg in 2011 as the Oregon-based company expanded east.

Inside This Issue

TAKING STOCK: . . . And Back In The U.S.

As has often been the case in my previous trips there, perhaps the leading topic of conversation at the Ligna show in Hannover, Germany in mid-May was the status of multiple new projects back in the United States, such as Roseburg’s new MDF plant in Oregon, Kronospan’s new OSB plant in Alabama, Hood Industries’ new softwood plywood mill in Mississippi and the discussion landed on some rumors that had been percolating.

Article by Rich Donnell, Editor-in-Chief, Panel World

UPDATE

- Roseburg Makes Major Decision

- Hood Announces New Plywood Mill

- Huber Takes Another Swing

- Kronospan Plans OSB Operation

- Mercer Takes Over Structurlam

- Sierra Pacific Plans Window Expansion

- CalPlant Files, Seeks A Buyer

- LP Continues Siding Growth

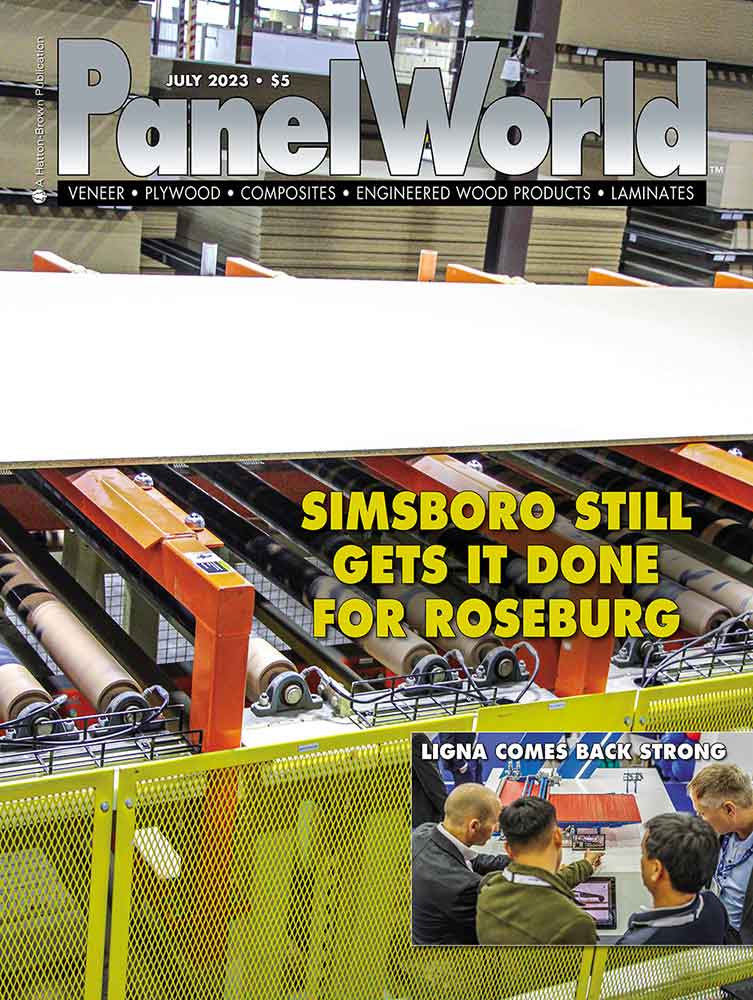

World Stage For Wood Products Industry Lives Up To Hype At Ligna 2023 In Germany

HANNOVER, GERMANY – Numerous machinery and technology companies in the structural and non-structural wood-based panel industry exhibited at Ligna 2023 held May 15-19, and they were part of a larger event that covered the entire range of forest products production from forestry to windows, as 1,300 companies from 50 countries exhibited, attracting 80,000 visitors from 160 countries, with everyone excited to be there following the missed 2021 event due to the virus.

Look for continuing coverage of developments at Ligna in the upcoming issues of Panel World.

Article by Rich Donnell, Editor-in-Chief, Panel World

FIRE TECH

EDITOR’S NOTE: The following companies submitted editorial profiles to complement their advertisements placed in Panel World July 2023.

- Clarke’s PyroGuard

- CMC Texpan

- Electronic Wood Systems (EWS)

- Fagus GreCon

- Firefly

- FLAMEX

PROJECTS

- Hood Orders Westmill Dryers

- Hood Taps Altec For Green End

- Thebault Orders LVL Plant From Raute

- Latvijas Finieris Plans Expansion

- Barlinek Gears Up With Hymmen Line

- Lumin Announces New Plywood Mill

- New MDF Plant Comes On Fast

- KEAS Starts Andritz Fiber Line

- Ethanol Firm Processes Straw

CLIPPINGS

- Luoma Announces Retirement

- Norm Voss Receives CPA Landry Honor

- CPA Recognizes Safety Leaders

- Wood Turbines Will Use LVL

- Egger Touts Recycling Center

- ADMARES Plans Housing Factory

- Universities Receive Mass Timber Grant

SUPPLY LINES

- WMF Returns September 5-8

- Westmill Going Strong At 48 Years

Find Us On Social

Simsboro Still Gets It Done For Roseburg

Article by Jessica Johnson, Senior Editor, Panel World

SIMSBORO, Louisiana – If you want to see a plant that can survive, you’re looking at it. Nestled off I-20, in a town so small the state of Louisiana calls it a village (the 2021 population estimate was 791) there runs a particle-board plant—first built by Willamette in 1971, assumed by Weyerhaeuser in 2001 as part of the Weyerhaeuser purchase of Willamette, then Flakeboard purchased it in ’06 (installing a melamine lamination line in 2009), and then sold to current owner Roseburg in 2011 as the Oregon-based company expanded east. Since then, Roseburg has continued to run the operation, called Simsboro Composites, with consistency and upkeep.

Current Plant Manager Cody Clark says production capacity is holding steady at 240-260MMSF, but could jump to 300MMSF with a few equipment changes that the team is currently looking at. “Not major changes,” he adds. “But definitely some investments if we choose to go that route.”

Perhaps the most important investment of all has been the emphasis on safety. Clark and Safety Professional Klay Koonce point to the operation’s 0.0 DART rate for the past 18 months. DART was developed by OSHA to provide a better idea of the impact of an employee situation. DART stands for Days Away, Restricted, or Transferred.

Koonce, who has worked at the Simsboro faciliy for a decade, says that it is easy for companies and facilities to say they put safety as a priority. At Roseburg, it is a value. “You can tell that on the floor, seeing improvements, that we are really putting safety as a top value. That goes a long way, a company that is willing to take care of you, and make sure you go home safe to your family at the end of the day. That is not a bad place to be,” Koonce says.

Clark agrees that by really pushing the value of safety, and not just giving it lip-service, has also improved the mill’s run rate—hitting production numbers that haven’t been see, ever. “Safe mills are mills that run well,” he says. “We are exceeding plans for production, having just sat a new weekly record.” Weekly targets aren’t the only thing being exceeded. One day, three different machine centers produced more than 1MMSF. Safe and happy Team Members work with pride, and that translates to increased performance.

“Any mill can get lucky in one week, but the way we’ve been running the last several months is astonishing,” Clark adds.

The key for Koonce is that he and the safety committee have been intentional with their behavior-based safety conversations and changes. He admits it has taken a while to get where they are now, but the mindset of Team Members has definitely changes. Safety meetings went from just grabbing pizza and talking, to tackling problems head on: Walking the floor as a committee and identifying potholes to repair; ladders that need to be replaced; adding machine guarding; housekeeping; fall protection; fire protection systems and more.

Want More Content?

Panel World is delivered six times per year to North American and international professionals, who represent primary panel production operations. Subscriptions are FREE to qualified individuals.

Newsletter

The monthly Panel World Industry Newsletter reaches over 3,000 who represent primary panel production operations.

Subscribe/Renew

Panel World is delivered six times per year to North American and international professionals, who represent primary panel production operations. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative. Contact us today!

Longtime executive and manager in the wood products industry, for years with LP, Brian Luoma announced he is retiring at the end of 2023 from his position as president and CEO of The Westervelt Co.

Longtime executive and manager in the wood products industry, for years with LP, Brian Luoma announced he is retiring at the end of 2023 from his position as president and CEO of The Westervelt Co.