NewLife Forest Restoration has ramped up production at its new engineered wood products plant in Bellemont, Ariz., while also increasing forest restoration work in service of its 4 Forest Restoration Initiative (4FRI) Phase 1 Forest Service stewardship contract that seeks to thin and treat more than 300,000 acres at risk of…

November 2021

November 2021

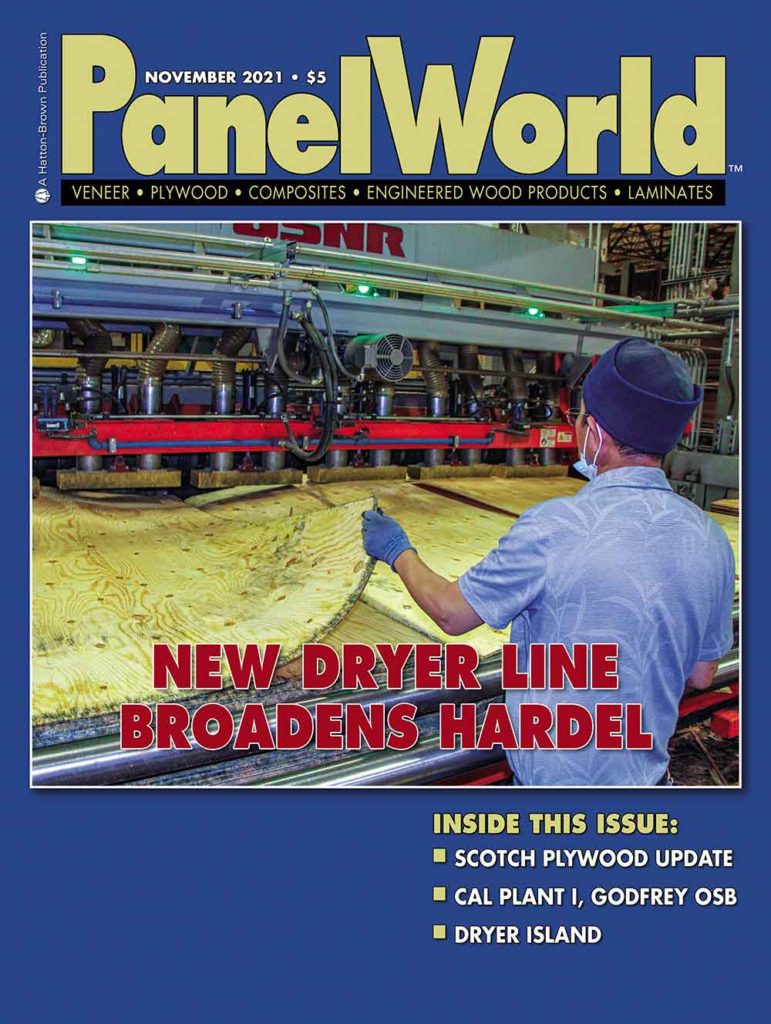

Cover: New Dryer Line Broadens Hardel

CHEHALIS, Washington – Working through a new dryer installation in 2020 was “perfect timing,” says Hardel Mutual Plywood General Manager Emanouel Piliaris, after the company started up a new USNR unit at the tail end of the spring 2020 COVID pandemic slowdown, and had the new machine ready to roll as the slowdown turned into some of the hottest forest products markets in history.

Article by Dan Shell, Senior Editor, Panel World

Inside This Issue

Taking Stock: Pandemic Felt Bad, Profits Felt Good

Given that Panel World is published six times per year, the November issue before your eyes represents the final issue of 2021. I’ve read through the six issues and pulled a few highlights of what went on in the panel world in 2021 as reported by Panel World. Actually, given that as I write this it’s only October 5, let’s call it a fiscal year dating back to October 2020.

Article by Rich Donnell, Editor-in-Chief, Panel World

UPDATE

- Cal Plant I Regroups, Sale Is Possible

- OSB Mill Still Possible In Arizona

- WKO Acquires SDS Lumber

- Roseburg Moves Forward In West

- New Life Starts Up EWP Operation

- PELICE Adds Keynoters, Exhibitors

Scotch Plywood Focuses On New Mill, Landowner Relations

WAYNESBORO, Mississippi – A mill fire is a devastating event on multiple levels and the January 6 fire that destroyed the Scotch Plywood Company veneer facility in Waynesboro was no exception. The fire occurred while the mill was in operation, and every on site employee, many of whom helped fight the fire, was accounted for and found unharmed.

Article submitted by Scotch Plywood, as written by Stamp Ideas for Forest Landowner magazine.

PROJECTS

- Pacific Wood Laminates Plans Veneer Drying Upgrades

- Metsä Anticipates New LVL Facility

- Starwood Plans Fiber Prep Line

- Dongwha Rolls With Acacia Species

DRYER ISLAND

EDITOR’S NOTE: The following companies submitted editorial profiles and images to complement their advertisements in Panel World November 2021.

- BÜTTNER

- NESTEC

- RAUTE

- USNR

- WESTMILL

- DÜRR SYSTEMS (DÜRR MEGTEC)

WVCO Continues To Provide Innovative Wax Products, Opens Wax Plant In Louisiana

PINEVILLE, Louisiana – Willamette Valley Company (WVCO) proudly points to its business model as standing on the pillars of dedicated service, high-quality products and state-of-the-art innovations to bring value to its customers.

Article submitted by Willamette Valley Co.

SUPPLY LINES

- NESTEC Names Deemer President

- Hymmen Reveals NA Cooperation

- Spurgin Heads Sales For LIMAB NA

- Haltbakk Leads Argos Solutions

- CMC TEXPAN Gears Up For Woodex 21

- S-W Purchases Resins Operation

- Digital LIGNA Makes Progress

- Heiner Wemhöner Reaches Finals

WHAT'S NEW

- Belt Monitoring

- Flying Panel Saw

CLIPPINGS

- Egger-Lexington Celebrates One Year

- Roseburg FP Joins WU+D Institute

- SLB, USDA Enhance Collaboration

Find Us On Social

New Dryer Line Broadens Hardel

Article by Dan Shell, Senior Editor, Panel World

CHEHALIS, Washington – Working through a new dryer installation in 2020 was “perfect timing,” says Hardel Mutual Plywood General Manager Emanouel Piliaris, after the company started up a new USNR unit at the tail end of the spring 2020 COVID pandemic slowdown, and had the new machine ready to roll as the slowdown turned into some of the hottest forest products markets in history.

The new dryer creates additional in-house capacity for Hardel, one of the biggest plywood producers on the West Coast, with 164 press openings. In addition, the facility has more control of its manufacturing processes and is less reliant on dry veneer purchased on the open market.

According to Piliaris, plant officials were looking to enlarge and upgrade its dryer capabilities to avoid having to buy as much dry veneer – sometimes up to 30% of incoming raw material – because in addition to overall quality and consistency concerns, dry veneer brings with it storage issues and also is more expensive and harder to source in the winter months.

Installed in spring 2020, the dryer started up in May last year and was running up to speed when prices and demand took off, reaching unprecedented highs this past summer. Piliaris remembers low order files and production in April and May. “Things picked up in June, then went through the roof,” he remembers with a smile. “And the dryer? What timing! We were very pleased with it.”

Want More Content?

Panel World is delivered six times per year to North American and international professionals, who represent primary panel production operations. Subscriptions are FREE to qualified individuals.

Newsletter

The monthly Panel World Industry Newsletter reaches over 3,000 who represent primary panel production operations.

Subscribe/Renew

Panel World is delivered six times per year to North American and international professionals, who represent primary panel production operations. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative. Contact us today!

Article by Rich Donnell, Editor-in-Chief,

Article by Rich Donnell, Editor-in-Chief,