● Karl Aicher, Director Project Engineering, Grenzebach

“Wood Fiber Insulation Batts: Properties, Use and Production Process”

This presentation will explain what wood fiber insulation is, the physical properties of WFI, how it compares to other insulation materials, where it’s used in buildings and how it is made— from wood chips to batts.

● Timothy Chaffee, Business Director, Wanhua Chemical (America) Co., Ltd.

“Closing Technological Gaps of Isocyanate Wood Binders”

While polymeric methylene diphenyl diisocyanate (PMDI) binders for composite wood products could be considered mature technology, a significant portion of the market continues using formaldehyde-based binders due to a perception that PMDI cannot work for them. Wanhua continues to innovate in the wood binder space and has closed many of the technological gaps that limit PMDI as an option for any composite wood products producer.

● Christian Dieffenbacher, CEO, Dieffenbacher

“Future-Oriented by Tradition: How 150-Year-Old Family-Owned Dieffenbacher Is Driving Digitalization and Sustainability in the Wood-Based Panels Industry”

Under the motto “150 years of transformation on solid ground,” German family-owned Dieffenbacher, a leading manufacturer of press systems and complete production plants for the woodbased panels industry, celebrated its 150th company anniversary in 2023. One of the threads that run through the company’s history is transformation. Dieffenbacher presses transform a wide variety of materials into useful products, while Dieffenbacher the company has permanently transformed itself to help industry and society address increasingly complex challenges.

● Cory Elliott, Senior Project Manager, Crow Engineering

“The Future and the Fundamentals”

Technological advancements have created opportunity for transformative change. Adopting AI based control systems will enable human like responses to the process, a constraint that has limited automation in the past. With this opportunity comes warning—knowledge of and adherence to process fundamentals will be evermore important to capture the opportunity these technologies create.

● Lorne Fardy, Director, Product Development, Kadant Carmanah Design; Conor McElveen, Sales Director, Aftermarket, Kadant Carmanah Design

“Using Smart-Connected Technology to Improve Stranding and OSB Production”

Decisions about how to set up, operate and maintain a strander and its components are traditionally influenced by the quality and throughput seen downstream at the press. To help green end production managers gain more visibility across their stranding operation in real-time, new Smart-connected technology is optimizing the productivity, efficiency and profitability of the stranding operation.

● Paul Gavin, Sales Manager (North America), Biele Group

“Digital Solutions and Production Control in Press Lines”

Biele Group is integrating digital solutions and capturing process data, turning them into valuable insights, to improve efficiency of the lines, minimizing rejects and allowing a more accurate and controlled production.

● Jeremy Goebel, Vice President, Con-Vey; Richard Lepine, General Manager, Argos Solutions

“The Automatic Panel Repair Line Journey—Latest Technology and Real-Life Experience”

This presentation will take you into the latest technology regarding automatic panel repair operation while looking at a real-life experience—the journey from Weyerhaeuser Kalispell in Montana who installed an ARGOS/Con-Vey panel repair line back in December 2021, as the pandemic was hitting the country. You will hear about the real results obtained, the learning from this project, and all the benefits from this technology.

● Stuart Gray, CEO, Roseburg

“Looking Back to Look Forward: The History and Future of Roseburg Forest Products”

The history of Roseburg illuminates its future. Key strengths that enabled the company to survive and thrive over the decades pave the path to continued growth and making more lives better from the ground up.

● Benjamin Hackbart, OEM Sales, Dürr Systems

“Optimizing Your APC $ystem”

Your air pollution control system can be costly to continue to operate as it ages, especially if poorly maintained. There are several main components that if addressed can result in big savings that will aid in minimizing emissions while also reducing operating costs. Walking through and taking a deeper dive into each component will help to identify common issues that will result in a quick return on your investment.

● Todd Havican, Sales Director, Fagus GreCon

“Emerging Technologies in Spark Detection and Extinguishing”

New technology in spark detection and extinguishing, including detection of the spectrum of ignition sources; and the importance of spraying patterns; and a new intelligent extinguishment module that helps predict maintenance to keep systems safer and more reliable.

● Steve Jaasund, Senior Product Manager, LDX Solutions

“Emission Requirements for the Wood Products Industry—What Will the Future Bring?”

Because the manufacturing processes that are the mainstay of the industry are known as significant sources of air emissions, the parallel development of emission control regulations has been a continuing concern and focus for the industry. Where will future regulations take the industry?

● Bo Johansson, V.P. Sales Building Material, Limab

“Benefits with In- Process Non-Contact Dimensional Measurements”

Laser based in-line solutions at several locations in the production line deliver high accuracy, minimize maintenance and costs.

● Greg Lewis, Vice President, Wood Panels Forest Economic Advisors

“Strong Demographic Tailwinds Will Support Wood Panel Demand Mid-Decade”

Following near-term market weakness in late 2023 and the first part of 2024, healthy demand growth resumes in 2025, and construction markets will improve and absorb the growth in capacity.

● Hanoch Magid, CEO, SMAR – TECH

“Revolutionizing the Wood- Based Panel Industry Through the Power of AI Technology”

New solutions can help wood-based panel manufacturers to reduce significantly the use of raw materials such as wax and resin, increase productivity, improve quality and stability, reduce environmental impact, and stay ahead of the competition.

● Torben Marhenke, Team Leader R&D, Fagus-GreCon

“Next Level of Panel Quality Measurement”

By using new and innovative measuring principles, the quality control of wood-based materials is raised to a new level. Laser spectroscopy makes it possible to reduce the measuring time for formaldehyde determination from six hours to 15 minutes. Also, a solution for three-dimensional particle classification is launched.

● Roy O. Martin III, Chairman, CEO, CFO, Martco

“Empowering Culture: Navigating Change While Preserving a Culture of Excellence”

As RoyOMartin is amid growth while facing upcoming organizational transitions, sustaining current company culture and empowering leadership will be crucial in navigating these changes, including the need to empower individuals within the organization to adapt and thrive while preserving the core values that define the current culture of excellence. Change should not be viewed as a threat to the established values and principles but rather as an opportunity for growth and adaptation.

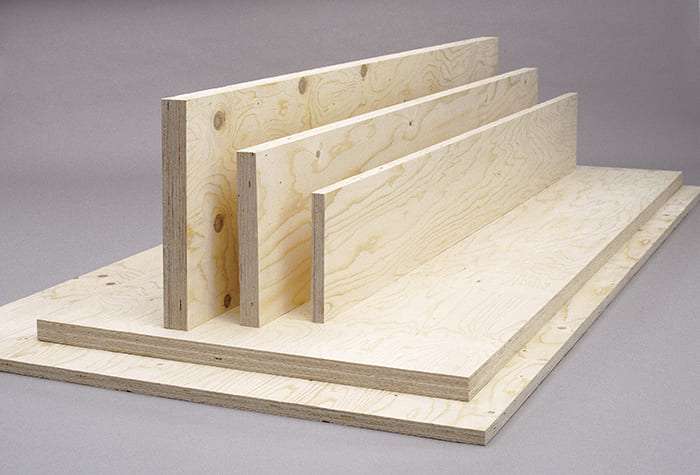

● Nick Milestone, Director, Project Execution, Mercer Mass Timber

“Innovation in Mass Timber and Hybrid Building Systems”

The learnings and innovations gathered through decades in the off-site construction industry have helped to develop a successful hybrid construction business model utilizing the key components of glulam, cross-laminated timber, structural timber cassettes, structural steel and light gauge steel framing technology for the residential, education, leisure, commercial and retail markets.

● Matthew O’Malia, Co-Founder, TimberHP

“Using Smart-Connected Technology to Improve Stranding and OSB Production”

A new generation of prefabricated, wood composite panels is coming to the North American market, outfitted with an ingredient that will change the future of renovation and new construction: high performing, carbon storing wood fiber insulation.

● Michael Spreitzer, Sales Engineer, Büttner

“Approach to Environmental Control Equipment”

With its newly founded environmental technology division, Büttner has established itself to be a complete system supplier for the wood based panel and pellet industry. Büttner’s portfolio consisting of energy systems, burners and dryers has been expanded by dry and wet electrostatic precipitators (ESP & WESP) to fulfill the environmental demands which will have an even bigger significance in the future.

● Guillermo Velarde, Principal, AFRY Management Consulting

“North American Wood Panels Outlook: Future Opportunities for the North American Industry”

Global macro-economic conditions and market constraints make the North American market an attractive region for exports, new investments, in both wood-based panels and engineered wood products, and acquisitions of existing assets. Understanding all the variables will be necessary today more than ever for domestic producers to take advantage of the opportunities that are to come in this market.

PELICE will once again be held immediately following the Wood Bioenergy Conference & Expo, which is scheduled March 12-13. Many of the exhibitors with technologies suitable to both the bioenergy and panel industries participate in each event.