smartlam installs ledinek glulam line

Slovenia-based Ledinek has embarked on a significant expansion across the Atlantic by supplying a new glulam production line to SmartLam North America for SmartLam’s mass timber manufacturing operation in Dothan, Ala.

Slovenia-based Ledinek has embarked on a significant expansion across the Atlantic by supplying a new glulam production line to SmartLam North America for SmartLam’s mass timber manufacturing operation in Dothan, Ala.

The SmartLam facility in Alabama has been producing cross-laminated timber and glulam since 2019, and has been using a Ledinek X-Press to produce CLT billets. Now, with the addition of the new, highly automated line for producing glulam, SmartLam will significantly increase its production capacity. The new glulam line is expected to start up in September.

With an annual capacity of 100,000 m³ = 42.300MBF, SmartLam’s Ledinek glued beam line will reportedly be the largest of its kind in North America, and will represent Ledinek’s first major complete undertaking in the U.S. market, highlighting its expanding influence internationally.

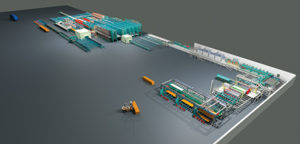

Ledinek has supplied SmartLam with the Kontizink H 4000 longitudinal fingerjointing machine and the Stratoplan planer. The delivery also included several types of presses, such as the Z-Press for wide face lamination, the high-performance Rotopress, and the multi-functional Flexipress. Additionally, Ledinek provided a band saw for longitudinal cutting of glued beams, a cosmetic station with an integrated turning unit for eliminating visual defects, the Superles 1300 planing machine for glued beams, and the XXL-Cut saw for cutting to length. All necessary material handling, from the entry of board packages to the stacking unit for finished beams, was also supplied.

Ledinek managed the entire electrical and software package, leveraging the expertise of engineers from its European headquarters.

In 2022 SmartLam announced it would invest $62 million to build a new dedicated glulam manufacturing facility of 140,000 sq. ft. with an annual production capacity of 84MMBF. Smartlam is also adding equipment to the CLT plant operation to reach 2 million cu. ft. of annual production, including a new high speed fingerjoint line with a radio frequency curing tunnel; new Costa 12 ft. wide panel sander; two, 10 tons cranes; a spray booth with 250 ft. of roll casing to semi-automate the CLT packaging line; and will be installing a new Hundegger UFA 3600 CNC that should be operational in early October.

Building on the success of the Alabama project, which began its commissioning phase in May, Ledinek started delivering equipment in June to another custom-made laminated beam factory in Pennsylvania for Rigidply Rafters. This facility will feature the an advanced laminated beam line capable of producing straight, camber and curved beams in a fully automated production flow.

Ledinek has adapted several machines to meet the specific requirements of the American product range. For split beams, Ledinek has developed a press capable of producing columns up to 24 in. x 78 in. in cross-section in a fully automated process.

To ensure efficient and continuous reliability, Ledink reports it will open a branch in North America and establish itself as a long-term partner for existing and future clients in the laminating timber industry.

Latest News

Peanuts And Crackerjacks

Article by Rich Donnell, Editor-In-Chief, Panel World July 2022 – Sometimes the mention of a wood products plant rings as true as an old ballpark. Houlton, as in Houlton, Maine, is one example. You might say Louisiana-Pacific has been playing at the same Houlton…

Pacific Woodtech Acquires LP EWP Division

Burlington, Wash.-based Pacific Woodtech announced the acquisition of Louisiana-Pacific Corp.’s EWP (I-Joist and LVL) division for $210 million. The acquisition includes LP laminated veneer lumber and I-Joist manufacturing facilities in…

Arauco NA Expands TFL Operations

Arauco has announced that it will invest $20 million to expand its thermally fused lamination (TFL) operations at its state-of-the-art particleboard mill in Grayling, Mich. The new lamination line will be Arauco’s third TFL line at Grayling and will increase the…

Find Us On Social

Newsletter

The monthly Panel World Industry Newsletter reaches over 3,000 who represent primary panel production operations.

Subscribe/Renew

Panel World is delivered six times per year to North American and international professionals, who represent primary panel production operations. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative. Contact us today!