Northwest Panel Industry Comes Together

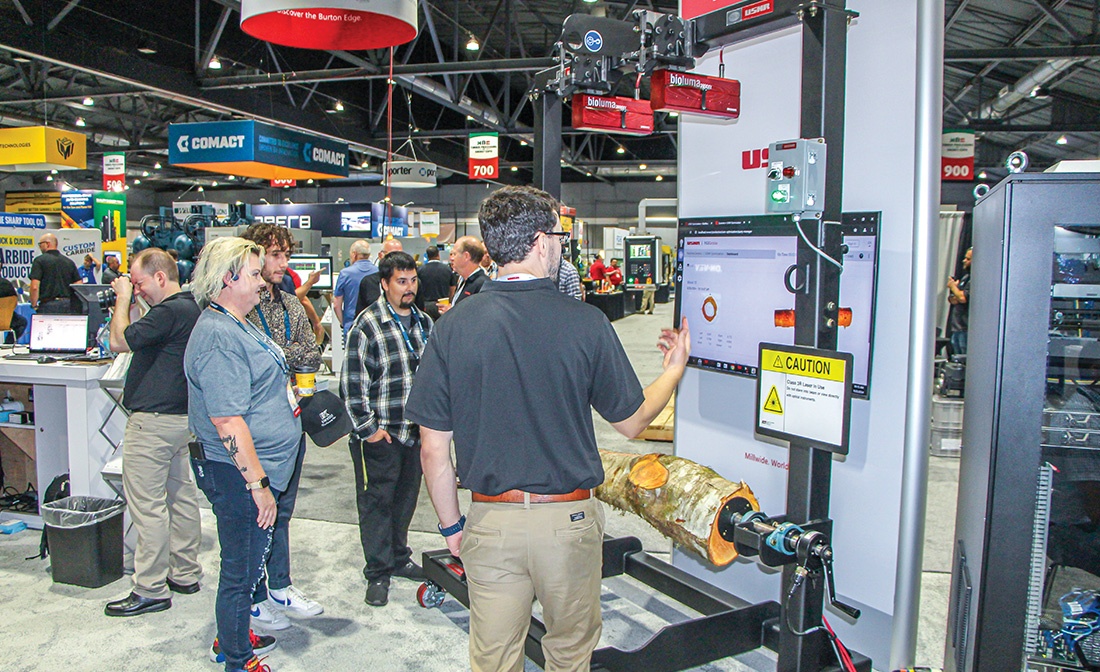

The 2024 version of the Timber Processing & Energy Expo (TP&EE), held September 25-27 at the Portland Expo Center in Portland, Ore., while as usual heavier to lumber manufacturing, once again drew significant players from the veneer, plywood and engineered wood products industries.

Nearly 1,200 attendees (non-exhibitors) registered for the event, which featured 180 exhibitors on 45,000 sq. ft. of booth space. The biennial event was the sixth TP&EE produced by Hatton-Brown Expositions, an affiliate of Panel World magazine, which served as a media host along with Timber Processing and Wood Bioenergy magazines.

The event included a mini-conference on “Panel Manufacturing Today.”

“Making Wood Matter: Automation Advancements Driving the Mill of the Future” was presented by Connor Eaton, account manager at Raute. Eaton reviewed the company’s versatile R-Series technologies integrated into Raute’s compact layup line and panel repairing stations, with customized options.

How do EWP producers gain an edge? “The answer is clear: embrace automation, AI, and deep data analytics to increase speed, efficiency, output and unit cost,” Eaton said, adding that AI solves two key pressure points for mills—data and manpower.

Eaton said the mill of the future is happening today, and pointed to Raute’s $93 million (Euro) contract for the technology delivery to a new LVL mill for Metsä Wood in Aänekoski, Finland.

George Harmati, Technical Sales Manager, Westmill, spoke on “Advancements in Dryer Technology,” and noted that recent projects for Westmill included the installation last summer of the world’s longest jet dryer at Roseburg in Coquille, Ore., and two new jet dryers for Hood Industries in Beaumont, Miss. with “dual heat” technology; and a new 400 ft. long, 10-deck fiberboard dryer for Huebert Fiberboard in Missouri.

Harmati reviewed the evolution of dryer technology, and pointed to more recent Westmill innovations in dryer design and material handling, including Westmill’s WestVac capture technology, now standard on new Westmill dryers; humidity control enhancements; and Westmill’s electrically actuated tipple.

The next TP&EE is scheduled for September 23-25, 2026 at the Portland Expo Center.

Latest News

Daniels, Pannell Join PotlatchDeltic

PotlatchDeltic Corp. has announced that Ryan Daniels and Bobby Pannell have joined the Wood Products division, with Daniels serving as Director of Operations, responsible for leading the manufacturing teams at the six lumber facilities and the St. Maries plywood mill, and Pannell serving as…

BE&E Purchases Conveying, Fabrication From BID

BID Group and Biomass Engineering & Equipment (BE&E) announced a strategic supply and outsourcing partnership, in which BE&E will acquire the Vibrapro brand and manufacturing operations located in Boise, Id., and the BID Group fabrication plant in Greenville, Ky…

Egger Starts Up Saturation Line

Wood-based materials manufacturer, Egger Wood Products, recently completed construction of a $22 million decorative paper saturation line at its Lexington, NC facility. The new line will infuse decorative papers with resin adhesive necessary for…

Acres Partners With Forisk

Acres, a data-driven land research platform that supports fast, informed decision making, is partnering with Forisk Consulting, a leader in analyzing timber markets and wood baskets, to visualize timber data for both companies’ clients. This collaboration…

Velarde Joins AFRY Team

AFRY Management Consulting has announced that Guillermo Velarde will lead the Wood Products and Surfaces Team in North America. Guillermo has been named a Principal Consultant at the AFRY’s New York office. He has more than 15 years of…

Wood Flooring Association Completes 71st Home With Gary Sinise Foundation

The National Wood Flooring Assn. (NWFA) has provided flooring for its 71st home in support of the Gary Sinise Foundation R.I.S.E. program (Restoring Independence Supporting Empowerment)…

Siempelkamp Expands Leadership Team

Siempelkamp Expands Leadership Team The Siempelkamp Group is realigning its Management Board to include seven members to bundle market-oriented core competencies together and integrate a modern management concept. Martin Scherrer, CEO of the Siempelkamp Group, will be...

Find Us On Social

Newsletter

The monthly Panel World Industry Newsletter reaches over 3,000 who represent primary panel production operations.

Subscribe/Renew

Panel World is delivered six times per year to North American and international professionals, who represent primary panel production operations. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative. Contact us today!